Drop on Thermoplastic Road Marking Material Reflective Glass Beads

Model NO.: EN, BS 6088, KS, JT and so on

Trademark: DAOHONG

Transport Package: 25kg/Bag or 1000kg/Bag

Specification: KS, JT, AASHTO M 247, BS 6088, EN and so on

Origin: Langfang, Hebei, China

HS Code: 70182000

Material: Glassbead

Application: Road Signs

Color: Water Clear

Size: 0-1180micron Glass Beads

Standards: Jt,Ks,En,BS 6088,Aashto M247

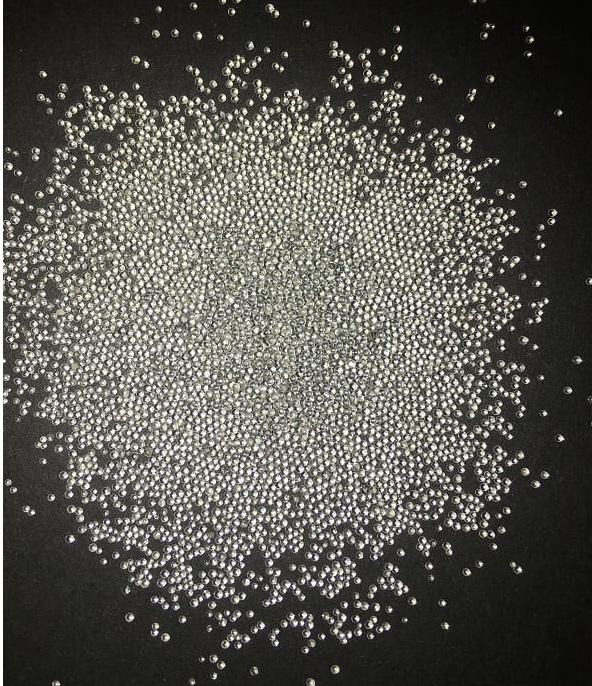

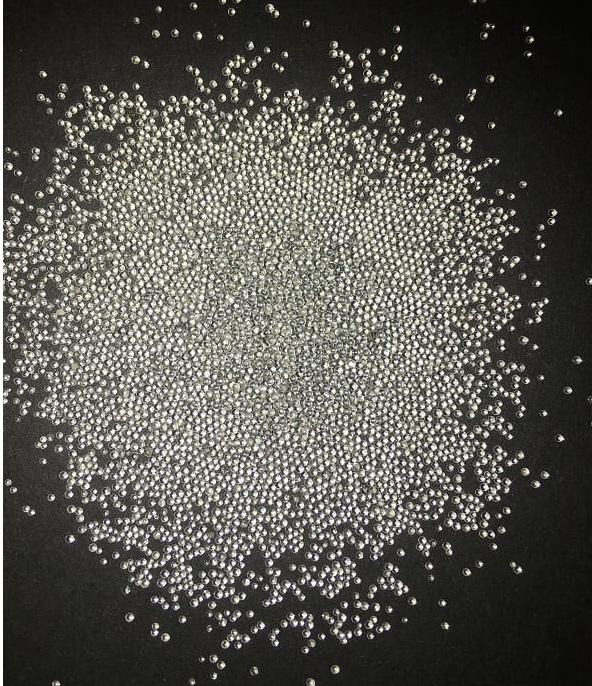

Reflective glass beads(retroreflective glass beads) are made of glass sand, after melting temperature the formation of a tiny glass beads, was observed under the microscope spherical, colorless, transparent, refractive index of 1.50-1.64 between the diameter is generally between 75 microns to 1400 microns Currently in the domestic production of major road Reflective glass beads craft flame floating method.

Reflective glass beads for road marking(paint) in the reflective material, can improve the retroreflective pavement marking paint performance, improve night driving safety, national transport sector has to be determined. When driving at night, the lights shone on road signs with glass beads online, make parallel light rays and reflected back, allowing the driver to see the way forward to improve the safety of driving at night. Now, reflective glass beads has become a road safety products, reflective material can not be replaced.

Reflective glass bead for road, mainly used in normal temperature, hot melt road marking paint, a method for premixed material can ensure marking period in the life of the long-term reflective; one kind of construction in the marking surface spreading, can play an instant reflection effect. coated glass beas are divided into two types, one as reflective highway A screen used as reflective. Coated glass beads is to use a high-performance organic materials on glass beads for external processing, making the glass bead surface adsorption air weakens the dust. as micro beads coated with a specific coupl-ing agent, to improve the adhesion of the coating bead and to prevent deposition of micro beads to the paint. Because of its function floatability. the use in the coating surface float, which has the largest surface area can be in creased more than 30% utilization.

Glass bead coating processing performance is more superior. It rains more often foggy in humid environments, with better reflective capabilities.

Technical parameters

Appearance: colorless transparent sphere, rounded and smooth, no obvious bubbles or impurities.

Circularity: round rate of≥80% Density:2.4-2.6g/cm3 refractive index:Nd≥1.50

Composition of: soda-lime glass composition, Si02 content of> 70%

English

English Chinese

Chinese Русский

Русский Español

Español العربية

العربية