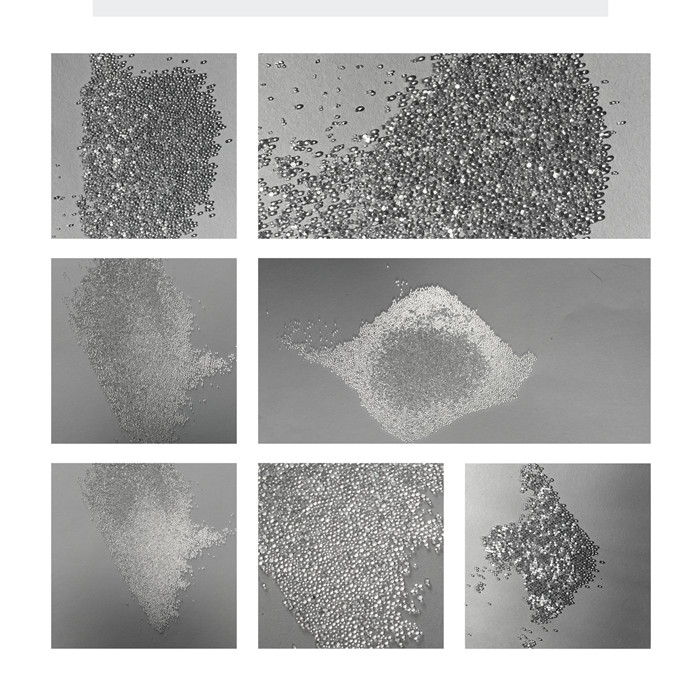

DH Glass Beads For Cleaning, Finishing, Peening And Deburring Applications

● Impart A Controlled, Clean Finish On A Variety Of Metals

● Clean Quickly Without Significant Metal Removal

● Clean, Finish, Peen And Deburr At Once

● Provide A Unique Surface Finish

● Can Be Recycled Many Times

● Contains No Free Silica

● Environmentally Safe

● Backed By Potters Technical Support

● Meets Both Mil And AMS Specs For Heavy Metal Limits

DH Glass Bead Media:

● Are consumed at a slow rate and can survive multiple impacts, allowing for continuous recycling of the media.

● Are chemically inert and will not leave ferrous or other undesirable residues on the surface of the workpiece.

● Impart a controlled, clean finish on a variety of metals.

● Clean quickly without significant metal removal. TYPICAL APPLICATIONS: Cleaning

● Cleans/preps surface of metal parts without changing tolerances, or imparting ferrous pollutants.

● Combines cleaning, finishing and peening in one operation. Finishing

● Creates a wide range of unique surface finishes that are easy to reproduce.

● Blends machine marks, seals pores and the results offer the advantages of glass bead peening. Peening

● Reduces the tensile stress in metal parts, increasing the fatigue limit.

● Reduces stress corrosion cracking. Deburring

● Removes burrs without damaging the parts and offers a peened surface in one operation.

DH GLASS BEAD FACTS:

Coarse Beads

● Remove larger, tougher soils; Peen to more intense levels; Peen to deeper zones in surface; Produce higher surface RA; Produce brighter surface; Consume faster at same pressure as fine beads; In practice, may consume slower than fine beads. Fine Beads

● Remove smaller, lighter soil; More impacts per pound; Clean faster; Peen to less intense levels; Peen outer zones of surfaces; Reach into keyways, filletes and small areas; Produce lower surface RA; Produce matte finish; Consume slower at same pressure as coarse beads; In practice, may consume faster than coarse beads.

All Beads

● Contains no free silica (environmentally friendly); Recycle many times; Clean efficiently at 45º- 60º nozzle angle.

Bead size, shape of the workpiece, angle of the nozzle, distance of the nozzle to the surface area, air pressure, and the type of delivery system (suction versus direct pressure blast) are factors affecting final surface appearance and media consumption parameters.

DH Sandblasting Glass Beads Package:

1. Using double-deck package, the inner is polythene film and its thickness is not less than 0.5mm; The outer is plastic woven bag to prevent leak or damp. The net weight of each bag is 25± 0.2kg.

2. Using double-deck package, the inner is polythene film and its thickness is not less than 0.5mm, the outer is plastic woven bag to prevent leak or damp. The net weight of each is 1000± 8kg.

3. According to clients' requirement.

English

English Chinese

Chinese Русский

Русский Español

Español العربية

العربية